EVA Cases

Custom Case Process

EVA case can protect your personal belongings very well.No matter digital products or qlasses and cosmetics,EVA case can be used to protect them.Our EVA cases are sold to dozens of countries and reqions around the world.

Add Value To Your Products.

Whether you’re a manufacturer of valuable products or a professional who wants to organize, protect, and transport your sensitive equipment, our custom EVA cases are perfect for you.

As a specialized manufacturer of EVA case with our facility, we produce bespoke EVA cases in-house, keeping costs within your budget without sacrificing style & quality.

With over a decade of experience in EVA case manufacturing process EVA cases for a variety of applications, we can work you through the whole process, from design to delivery.

EVA CESE PROCESS

Take a closer look at our capabilities & techniques

Custom Case Design & Engineering

Don’t worry if you have only a sketch or a rough idea.

By fully understanding your custom needs, our design team with come up with a 2D/3D design in as soon as 1 day.

During the process, to ensure that we design our EVA case for functions, style, and manufacturability, every detail is taken into consideration like:

- If the style meet your target market and brand identity

- If the design is feasible and cost-effective in production

- The balance between materials and budget

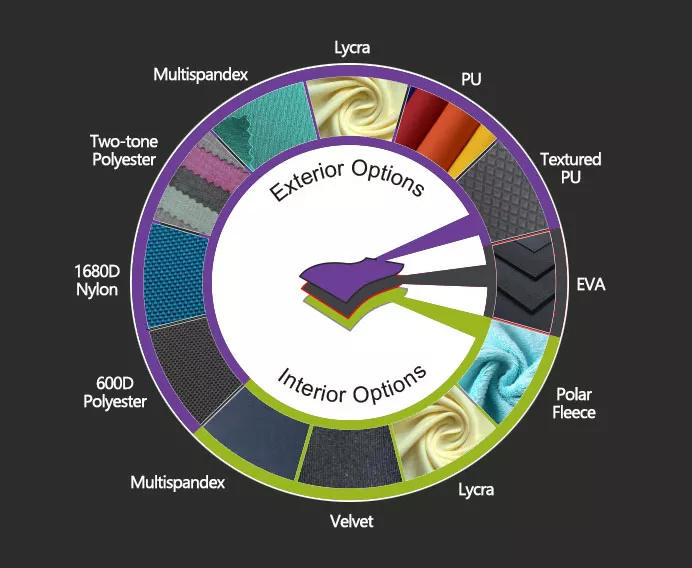

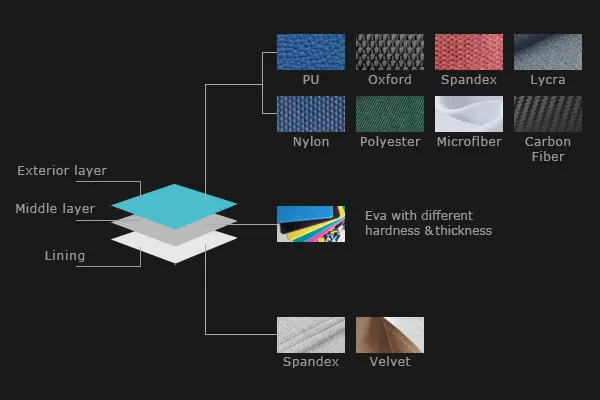

Shell Customization

Impressive looking starts from fully-customized outer shell

At Baipa Case, we offer numerous custom choices for you to create the outer shell of your EVA case.

With strong molding capability, we can make your case into any shape as required. Depending on the content inside, you have the choice to make your case softer or harder with EVA featuring different density. And a lot of options for exterior and lining materials are available based on your target markets and budget.

A fully-customized out shell ensures that your product/ delicate equipment always stands out with a stylish look while being fully protected.

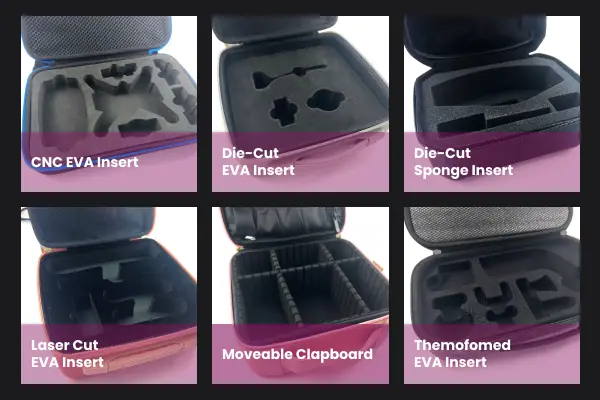

Foam Customization

Precisely-made To Ensure A Custom Fit

Tailor-made foam inserts prevent your products/ equipment from sliding around in the case and keep everything firmly in its place.

At Baipa Case, we can help you to make foam inserts customized to the content inside in terms of:

Size & shape:Cut or thermoform to the exact size and shapes based on the content inside.

Color: Available in all Pantone colors.

Density:Different levels of density available in various types of foams like polyurethane foam.

Function:Anti-static, conductive & other functional foams for specific products/ equipment.

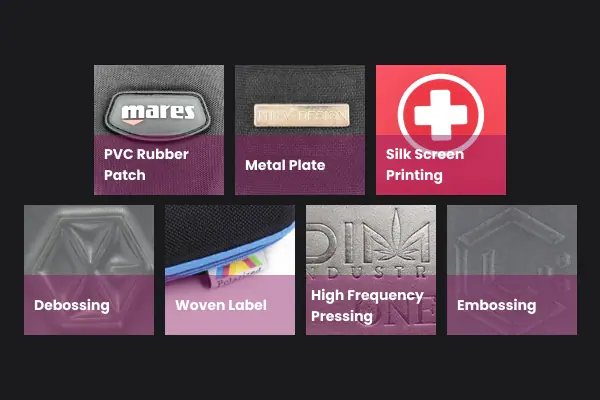

Logo Customization

Improve Brand Awareness With Custom Logo

One of the important components of a brand is the logo because as the “face” of the business, a prefect logo can make customers remember.

A custom logo on your EVA case makes your products uniquely yours and helps to improve your brand awareness.

Depending on your logo design, your brand identity, and your budget, we offer a wide range of ways to put your logo on the case shell, zipper, or label.

From printing to embossing to embroidery, you can choose the one that best shows your logo and brand.

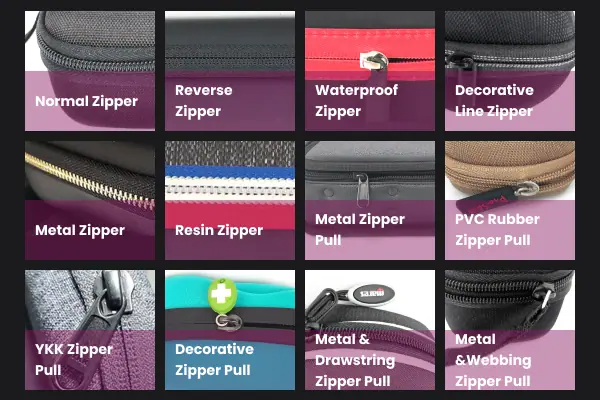

Zipper Customization

A good zipper makes your case more beautiful and practical

The perfect zipper gives you a very nice sense of experience, and the puller highlights its brand.

The zipper is an important part of the quality of a case.

So, we pay great attention to the choice of zipper!

Pocket Customization

Improve the sorting ability of the box

Precisely-made To Ensure a custom fit the pocket can contain many small things and parts, such as data lines, cards, tools and pens.

The pocket Improves the classification and storage capacity of the entire EVA box, making your EVA case more practical and beautiful.

We will design pockets with different materials and functions for customers.

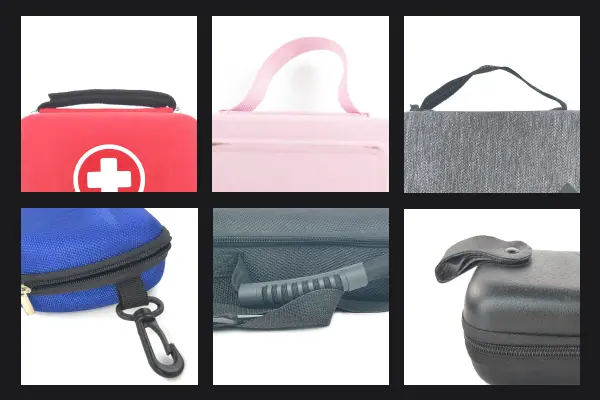

Carry Strap Customization

A suitable handle can improve the grade of EVA cases

Different box shapes, sizes, colors, materials and different handles will make the whole box more beautiful.

In addition, a suitable box handle can improve the practicality of EVA cases

Production delivery

Fast Tooling

The tooling of our EVA case is faster and less costly compared with that of plastic & metal case.

With our CNC tooling plant, we’re able to develop your custom mold in as quickly as 5 to 7 days. In this process, our team ensures the precision of your tool with repeated tests and modifications in-house.

The rapid and accurate tooling makes sure that you receive an exact-fitting EVA case in a shorter period.

In-house Prototyping

This process is where our collaborative idea comes into reality.

To avoid any error during the mass production, we will not proceed into the manufacturing stage before you approve the prototype.

The prototyping normally takes only 5 to 7 days thanks to our large stock of commonly-used materials and advanced CNC machines.

Streamlined Manufacturing

Just sit back and wait while we’re working the magic in our factory.

At Baipa Case, we have a streamlined process for our mass production, from laminating to cutting to thermoforming to stitching to trimming.

With every step taking place in the separated workshop by specialized workers, we ensure both the production efficiency and quality of your custom EVA cases.

Depending on the availability of the materials, this process will take 1-3 weeks.

100% Inspection

Every single EVA case will go through a strict inspection before delivery.

During this process, we will check an inspect everything from exterior appearance to size to the smallest accessory carefully to make sure there’s zero defect.

Our 100% inspection means that every case you receive is of the same high quality.

WRITE TO US

Upload your draft, CAD design or just talk with us about your rough ideas and custom needs, our case experts will get back to you within 24 hours.